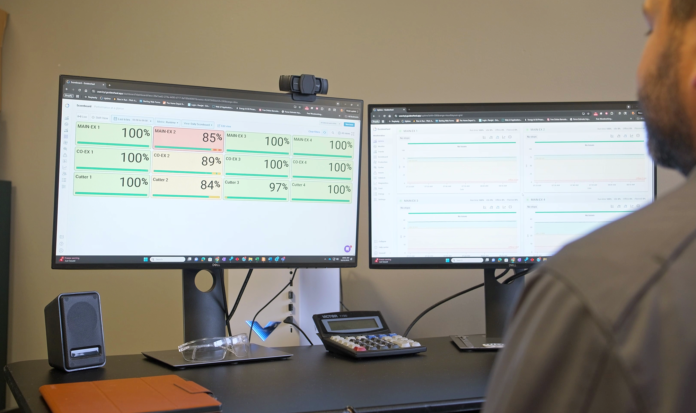

Interfab Shirt Manufacturing Ltd. (ISML), a unit of Viyellatex Group, has implemented Solvei8’s Factory OS to digitize and streamline machine maintenance operations. The transformation began with the deployment of Maintaini8, the platform’s maintenance module, enabling real-time tracking and coordination across the factory floor.

Operating 21 production lines with over 1,100 machines, Interfab sought a solution to reduce downtime and improve maintenance efficiency without increasing reporting burdens. Maintaini8 now provides real-time visibility into machine breakdowns, escalation processes, and resolution status, strengthening coordination between maintenance and production teams.

The platform was deployed factory-wide within 14 days using a train-the-trainer model. Within weeks, Interfab reported a 15% reduction in machine downtime, along with improved spare parts management and faster response times.

By shifting from reactive maintenance to a data-driven approach, Interfab has strengthened operational control and laid a foundation for scalable digital transformation across its manufacturing operations.

Interfab Cuts Machine Downtime by 15% with Solvei8’s Factory OS

RELATED ARTICLES